New Atomizer Parts for Flue Gas Desulfurization Units

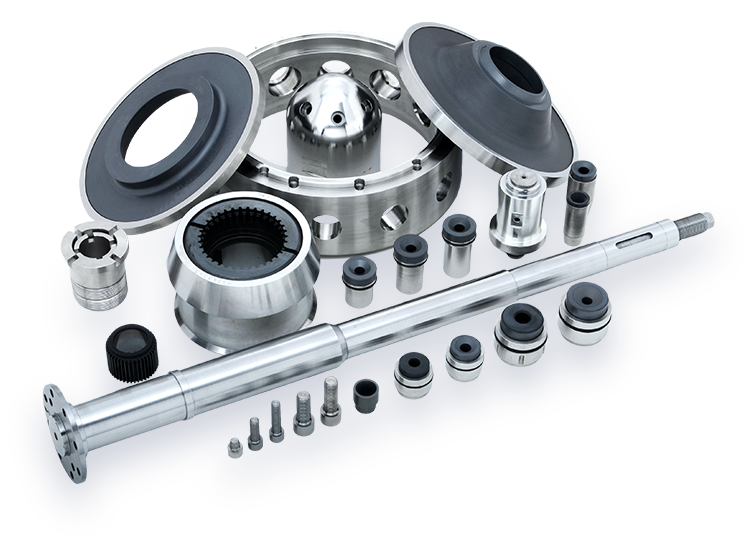

RPM Solutions manufactures new and rebuilds used rotary and stationary atomizer components for flue gas desulfurization units used in coal fired power plants, waste-to-energy centers, and incinerating facilities. These components are also utilized in other spray dryer applications.

RPM Solutions, a Rapid City, SD business, was formed in 1996 by Rob Mudge, Deb Mudge, and Shawn Veurink.

The company stocks approximately two hundred different components for these systems. Materials include stainless steels, titanium, Hastelloy, and advanced ceramics. RPM Solutions applies its manufacturing and engineering expertise to create cost effective wear solutions. RPM Solutions has been awarded patents for these designs.

Browse our online Parts Catalog and be sure to check out our Reverse Taper Nozzle technology. Our reverse taper nozzle design is engineered to optimize spray patterns, improve lime usage efficiency, and increase wear life.

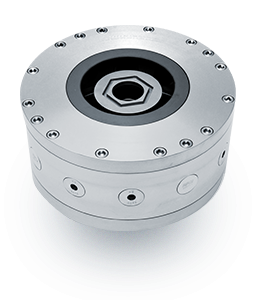

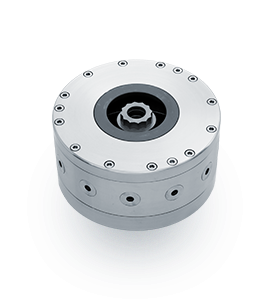

Atomizer Wheel Design Samples

Shown below are four typical titanium atomizer wheel designs. Each has several unique features that increase wear life and make that parts easier to maintain.

Click on the atomizer wheels below to see detailed information about their unique features.

Balancing Services

RPM Solutions offers balancing of atomizer wheels and atomizer spindles and shafts. New and rebuilt atomizer wheels are balanced as an assembly by adding strategically placed weights to the atomizer wheel for the proper correction.

Structural material is not removed and does not conflict with wear on these components and does not conflict with subsequent rebuilds. New and rebuilt atomizer spindles and shafts are typically corrected by removing material in non critical areas.