Cone Nut Design Changes

RPM Solutions has implemented design improvements on cone nut to increase the wear life and eliminate wear on the atomizer spindle.

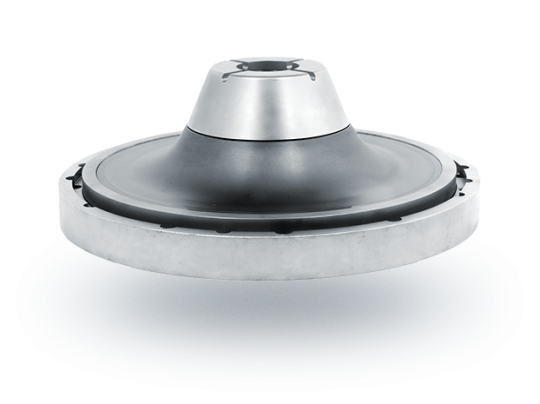

Cone Nut-Modified (New)

0 Hours of Runtime

The Cone Nut-Modified has been RPM’s standard for many years. The modified design employs a stepped area between the cone nut and the ceramic lower wear ring that prevents slurry from reaching the drive plate stem.

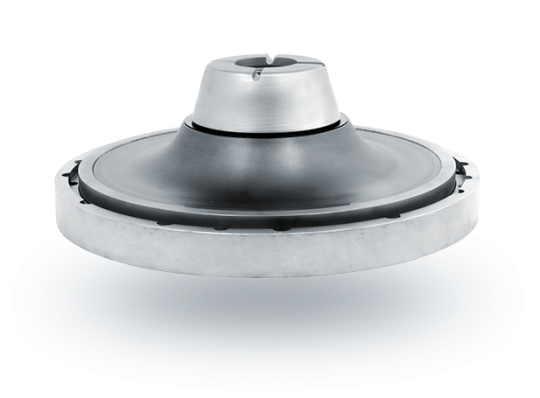

Cone Nut-Modified (USED)

3,370.17 Hours of Runtime

The Cone Nut-Modified shown has approximately 0.500” of material worn off the diameter after 3,370.17 hours of runtime, provided by RPM Solutions’ Atomizer Monitoring System (AMS). There is some minor wear around the machined slots on top of the cone nut that are used to install and remove the cone nut-modified. Wear also occurred on the atomizer spindle that triggered the thoughts that improvements needed to be made to the design.

Cone Nut-Modified-Long (Used)

2,668.03 Hours of Runtime

This worn Cone Nut-Modified-Long shows approximately 0.020” of material worn off the diameter after 2,668.03 hours of runtime. Once again, the runtime information was provided by RPM Solutions’ Atomizer Monitoring System (AMS). The four slots on the top of the standard cone nut- modified have been replaced with a hex that is not exposed to the outside diameter. The hex area filled up with slurry and prevented any turbulent wear in this area. This cone nut covers the entire atomizer spindle, thus no wear occurs. This customer is experiencing a substantial wear life increase with the new Cone Nut-Modified-Long.

* – Note that actual wear rate depends on environment. Your specific results may vary.