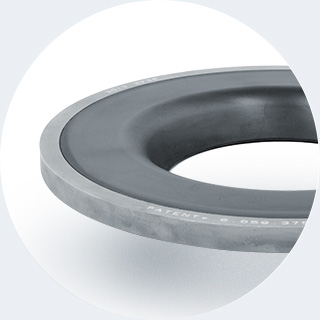

Upper Wear Ring. Ceramic. Metallic. Fantastic.

For over a decade, RPM Solutions’ upper wear ring and lid design has provided a seamless surface for the slurry to enter the atomizer wheel. This design prevents slurry from working its way underneath the upper wear ring, which could cause the upper wear ring to crack and break during operation. Our standard wear insert is made from a hardened wear resistant metallic material. Recently, an optional upgrade to a ceramic wear insert for applications with extreme wear and corrosion rates was added.

To highlight the benefits of the ceramic upgrade, the

example shown illustrates both metallic and ceramic upper wear rings from the same plant. The hours for each wear ring are provided by RPM Solutions’ Atomizer

Monitoring System (AMS).

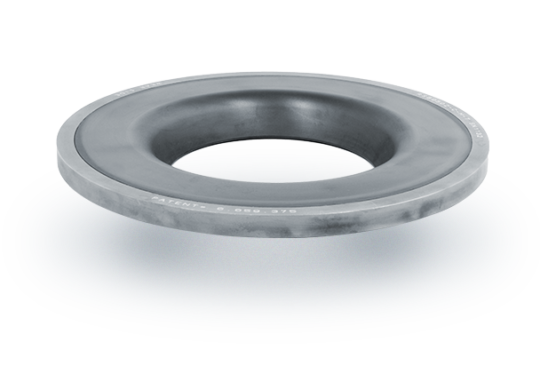

Upper Wear Ring

Metallic – Titanium – RS89502-M-T

4,590.13 hours of runtime… The metallic version has a wear groove of over 0.400″ deep.

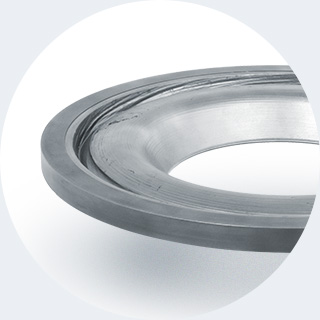

Upper Wear Ring

Ceramic – Titanium – RS89502-C-M-T

6,314.78 hours of runtime… The ceramic upper wear ring shows no wear.

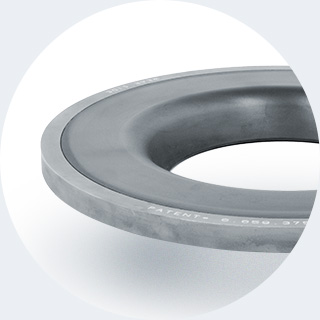

Upper Wear Ring

Ceramic – Titanium – RS89502-C-M-T

12,167.87 hours of runtime… The ceramic upper wear ring still shows no wear.

LONGER WEAR LIFE WITH THE CERAMIC UPGRADE RESULTS IN AN OVERALL LOWER COST OF OWNERSHIP.