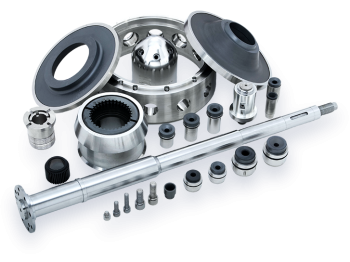

RPM Solutions manufactures new and rebuilds used rotary and stationary atomizer components for flue gas desulfurization units used in coal fired power plants, waste-to-energy centers, and incinerating facilities. These components are also utilized in other spray dryer applications.

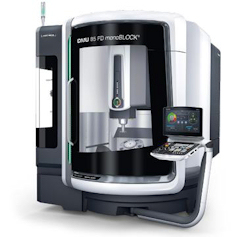

DMG MORI – DMU 85 FD monoBLOCK®

5 axis milling and turning CNC machine.

Highlights

- Complete machining through milling and turning on one machine in one clamping

- Milling / turning table with Direct Drive technology for up to 800 rpm.

- 40.9 × 23.2 in. maximum work piece dimensions and 2,645 lbs. maximum work piece weight

- Swivel rotary table also as a tandem drive for even more stability and dynamics

- Powerful 18,000 rpm. motor spindle with 46.9 hp. and HSK-A63 in the milling / drilling package

MORI SEIKI DURACENTER 5

4 axis Vertical Machining Center

Highlights

MORI SEIKI NL 2500

Rigid and precise CNC Lathe

The NL series stands for high stability and precision which surpasses conventional lathes and continues to set a global mark in mechanical engineering. The drive is installed directly into the turret for increased milling capacity and improved accuracy.

Highlights

- Innovative turret head design

- Best turning properties

- More precision and performance

- Digital tailstock

- 20-station turret specification

MORI SEIKI NL 3000

Rigid and precise CNC Lathe

The NL series stands for high stability and precision which surpasses conventional lathes and continues to set a global mark in mechanical engineering. The drive is installed directly into the turret for increased milling capacity and improved accuracy.

Highlights

-

- Innovative turret head design

- Best turning properties

- More precision and performance

- Digital tailstock

- 20-station turret specification